Application field

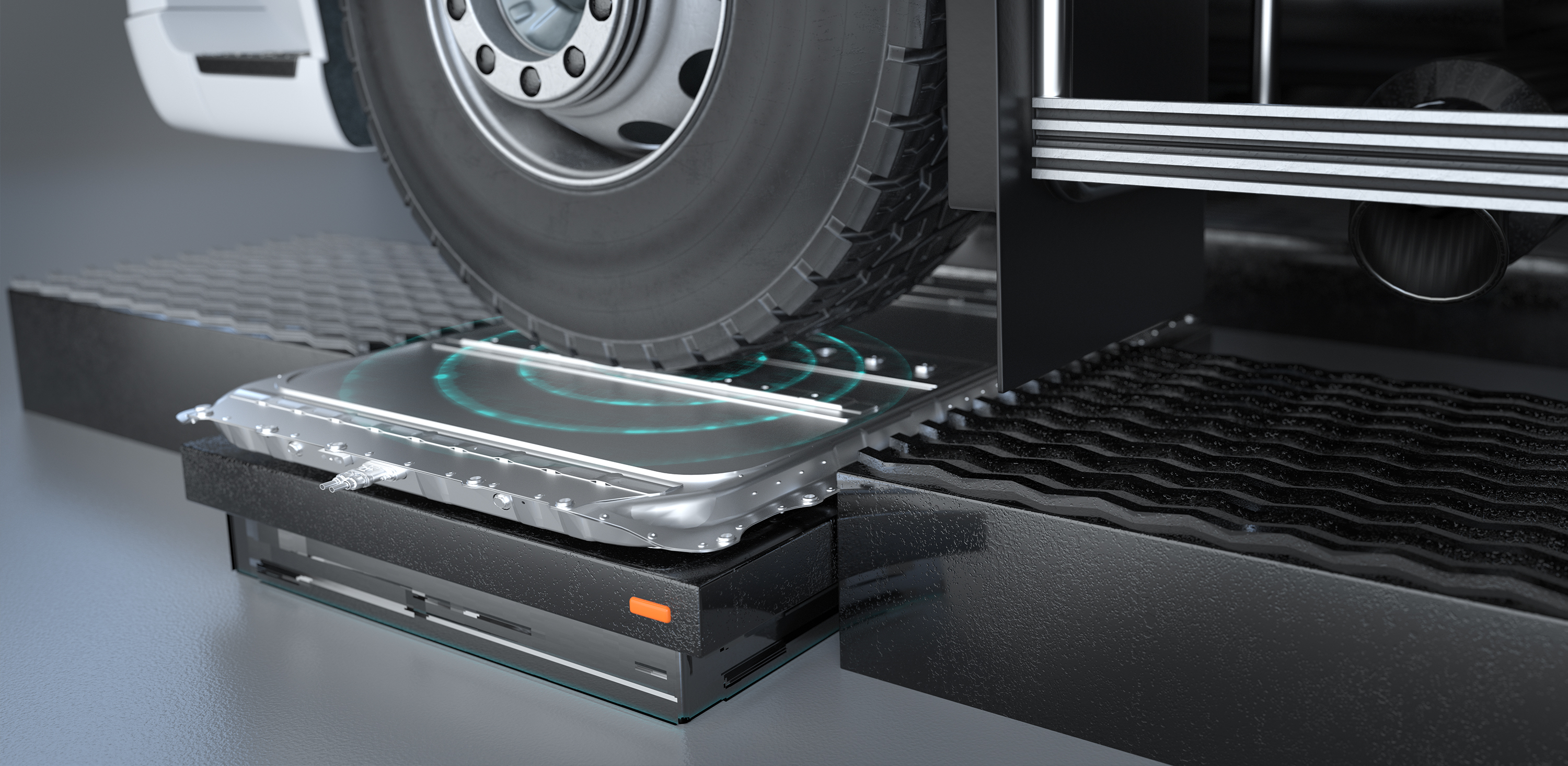

Passenger vehicle

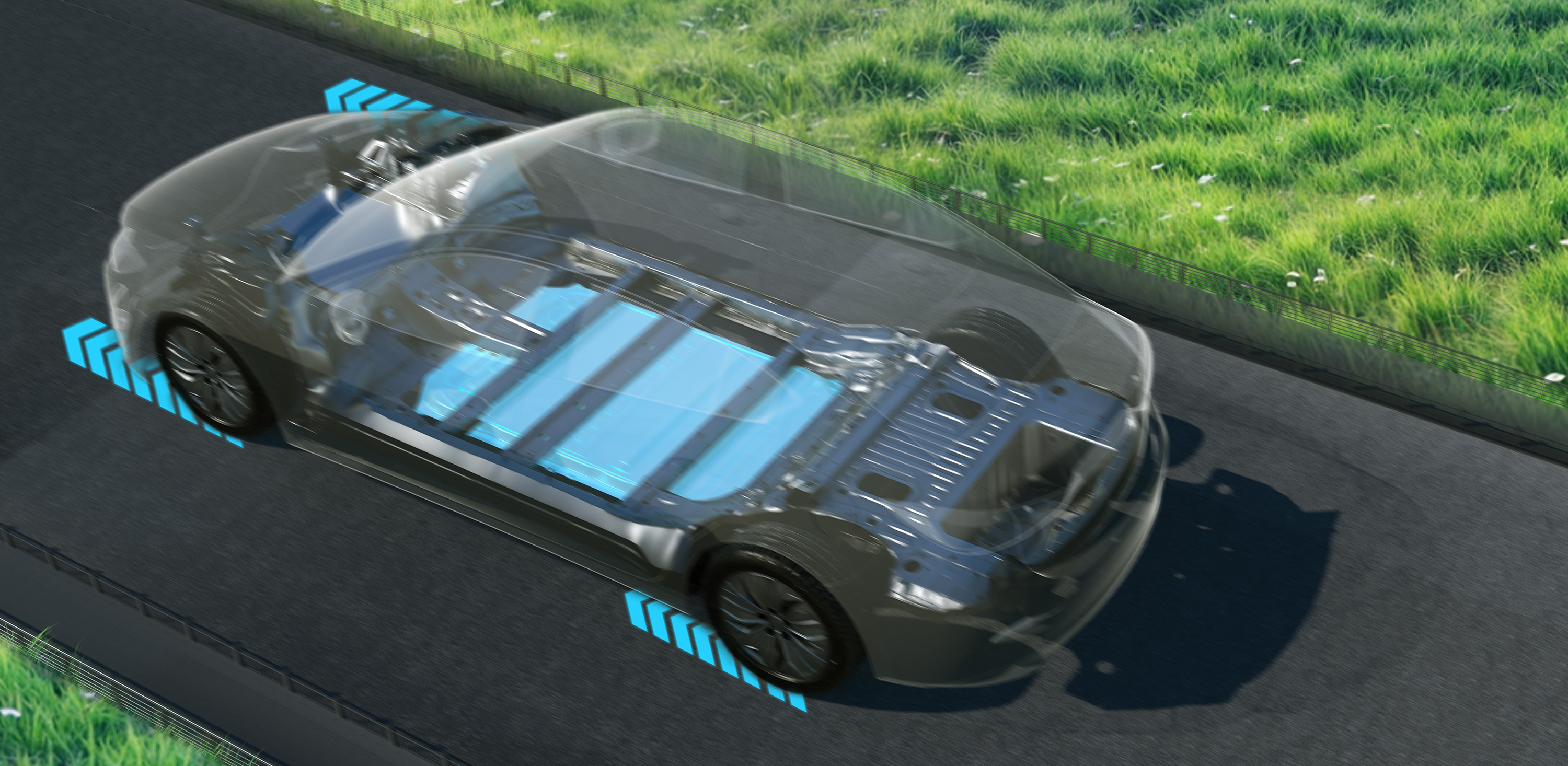

Commercial vehicle

7S

Super safety

Super strength

Super range

Super low-temperature

Super power

Super service life

Super cost

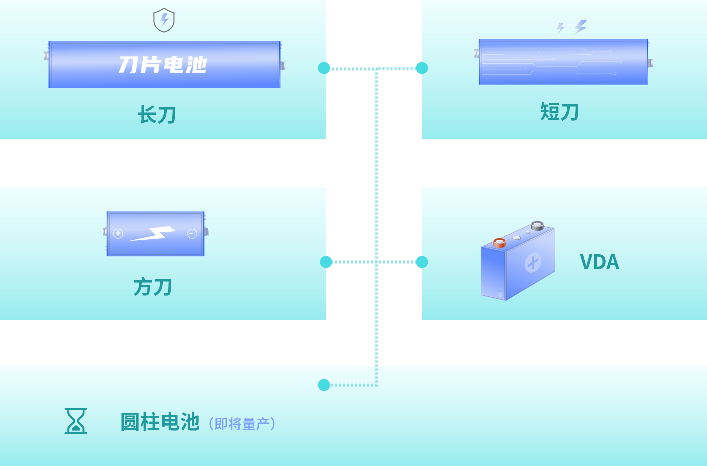

Product type

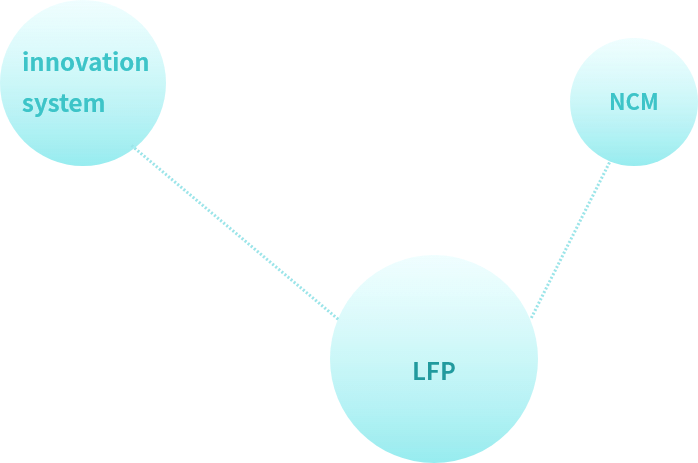

Chemical system

PACK capacity

Traditional battery pack GP

With module

Low volumetric cell to pack ratio

High cost

Before 2018

Blade battery CTP

Without module

Volumetric cell to pack ratio increased by 50%

Cost reduced by 30%

2020

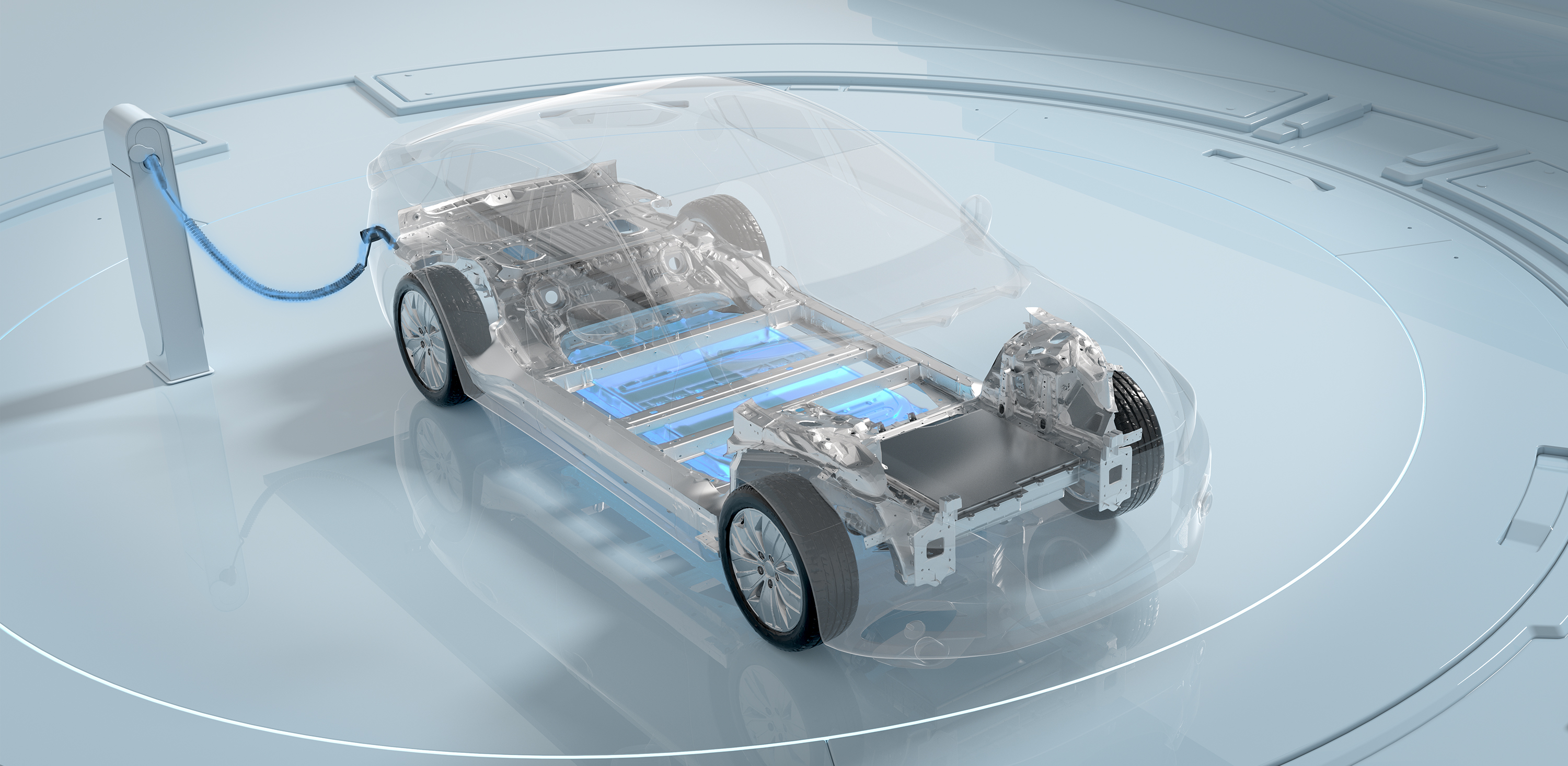

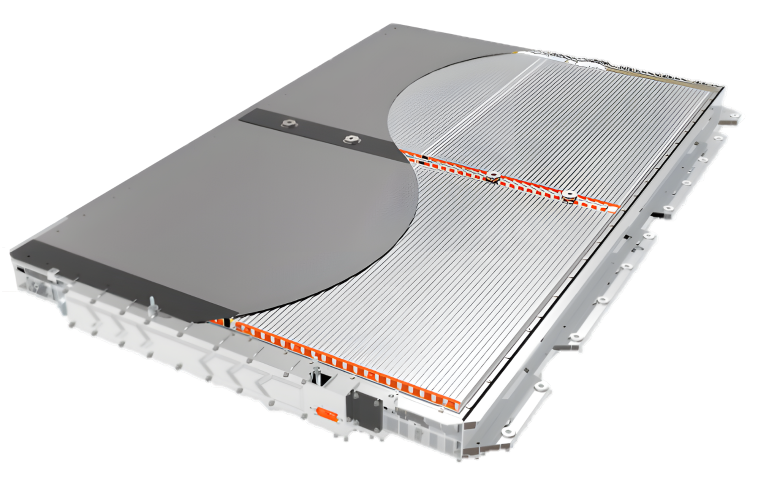

Blade battery CTB

Integrated body and cell design

Volumetric cell to pack ratio further increased by 25% (Vs CTP)

2022

Structural advantage of CTB

Cost advantage

Economical blade battery

Number of parts reduced by 45% when compared with a traditional battery pack

Overall cost reduced by more than 30%

High production efficiency

Simple design

Steps such as welding and fixing of the body skipped

Production efficiency increased by 60%

High volumetric cell to pack ratio

Volumetric cell to pack ratio up to 80%

Less space used

Large space for traveling without limitations

Ultra long range

SOC more than 150 kWh

High compatibility

Customized cell size

Arrangement adjusted according to the body width

CTB

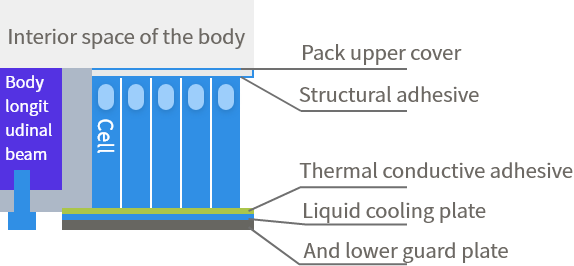

When compared with the CTP scheme, the CTB scheme adopts a further integrated structure in which the battery cover replaces the body floor to realize the integration of the body floor and chassis, which fundamentally changes the installation form of the battery.

Structural advantage of CTB

When compared with the CTP scheme, the CTB scheme adopts a further integrated structure in which the battery cover replaces the body floor to realize the integration of the body floor and chassis, which fundamentally changes the installation form of the battery.